Precision forging straight bevel gear forging production line the process

Planetary gears, axle gears are straight bevel gear , straight bevel gear precision forging process has been used for mass production of cars, tractor differential planetary bevel gears, axle bevel gears and agricultural machinery, engineering machinery transmission box Bevel gears, compared with the cutting process, production costs can be reduced by 20% -40%. According to the difference of the accuracy requirements of the user, the forging process also has a great difference, for high-precision automotive differential gear, also can be used hot forging plus cold finishing, this process, after heat treatment, the gear accuracy can reach 7 levels,For the accuracy of the agricultural machinery is not high, you can use a fire for three forging or a two forging process, the specific process is as follows:

-

Hot forging and cold finishing process

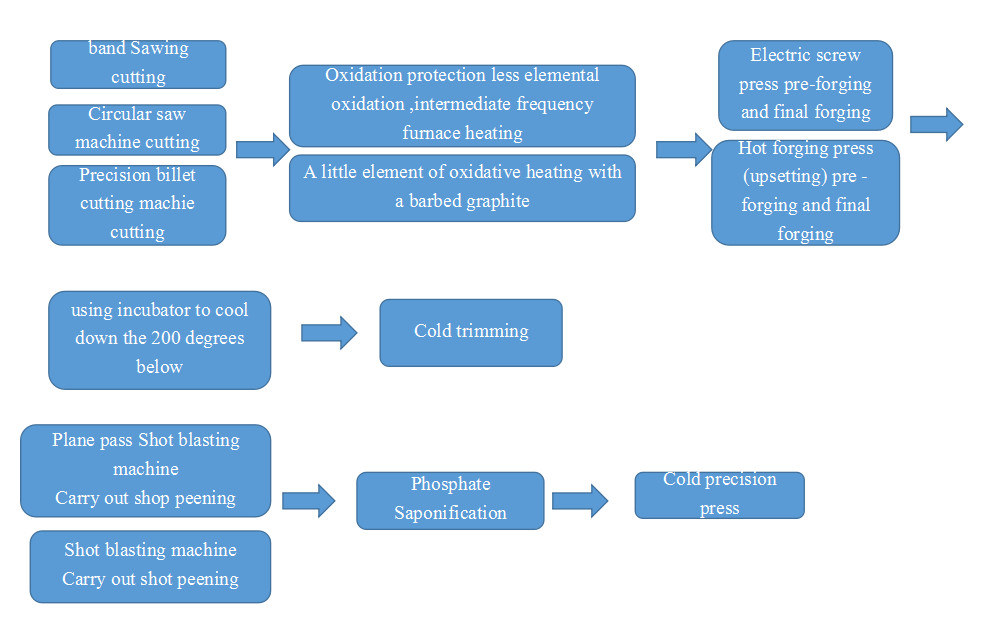

Cutting with a band sawing machine, circular saw or high precision billet shearing machine cutting , requiring smooth face, no shear defects. Heating with less no oxidation heating, to ensure that the surface less oxidation and haven’t surface defects, there are two heating equipment: the first is a nitrogen-protected IF induction furnace, and has a rapid discharge mechanism to reduce the oxidation in the outside of the furnace, to ensure that the teeth Shape accuracy, heating temperature control at 950 degrees, the electric furnace power, according to the production beat to determine. This is related to the selection of forging equipment, the higher the production efficiency, the greater the power of the furnace, in order to save labor, can choose with automatic feeding function of the furnace, nitrogen protection is to reduce the oxidation, Nitrogen source can choose industrial nitrogen machine. The second is a new type of heating furnace, at first ,making bar heated to about 200 degrees, and then sprayed with the bar for the casting of graphite, water-based graphite in the rapid evaporation of water at high temperatures, bar in the graphite layer of the package, High temperature heating section does not produce oxidation, to achieve the purpose of less no-oxidation heating. Forging can be used electric screw presses or hot forging presses, the process is basically pre-forging and final forging

Electric screw presses are generally forged on two devices, hot forging presses are usually for three-station forging, upsetting , Pre-forging and final forging. After forging ,in order to reduce oxidation, The isothermal normalizing is not carried out, using incubator slowly to cool down the 200 degrees below, when we need carefully to place the work piece in the incubator, to ensure that tooth surface haven’t bump. After Forging ,cold cutting edge, starting the process of surface treatment, in order to prevent tooth surface knock, adopting Plane pass or planetary wheel type Shot blasting machine.The forgings processed by shot peening , After phosphating saponification , carry on cold press in the fine press, to ensure that the precision, precision press recommended to use high-precision hydraulic press, a higher Cost-effective.

-

Hot forging process

Hot forging process and the before - mentioned process is exactly the same, but removed the cold finishing.

precision forging gear block diagram

1. Hot forging and cold finishing process

straight bevel gear forging production line process analyics

Precision forging gear is a mass production process, cutting with Band sawing machine have a low efficiency , The circular saw machine is equivalent to 3 - 4 times the efficiency of the band saw machine , high precision hydraulic shearing machine have the highest efficiency, but the price is expensive. So the circular saw machine is a higher Cost-effective equipment, less oxygen heating equipment both can be done . the combination of Forging equipment Two electric screw press is easy to realize automation, production efficiency is slightly lower than with the step beam of hot forging presses, and is similar to manual operation of the hot forging press, but less investment, equipment is easy to maintain. Shot blasting machine with planetary wheel ,the effect of shot peening is good, the equipment is running smoothly, the high degree of cold gear use cold precision process.

straight bevel gear forging production line project case

Precision forging straight bevel gear forging production line

Precision forging straight bevel gear forging production line

Precision forging straight bevel gear forging production line

Precision forging straight bevel gear forging production line