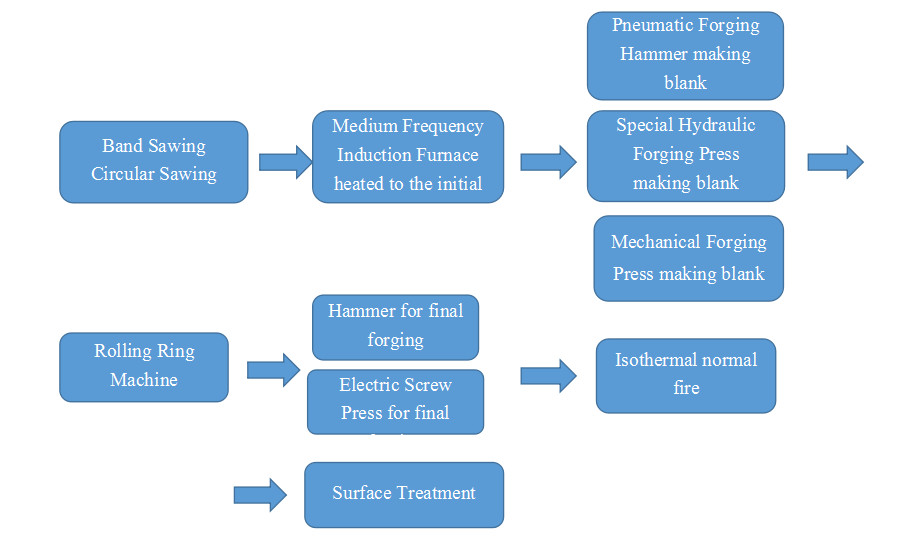

Basin Gear Forging Line Production Process

Band Sawing or Disc Sawing - Medium Frequency Induction Furnace Heating - Pneumatic Forging Hammer, Special Hydraulic Forging Press, Mechanical Forging Press making ring and forging rough blank - Rolling Ring Machine making ring - Hammer or Electric Screw Press Final Forging Forming - isothermal normalizing - Surface Treatment.

Basin Gear Forging Line Flow Chart

Basin Gear Gorging Line Process Analysis (Comparison)

Cutting: The weight of the basin gear is usually 35-60 kg. Bar diameter is usually Ф120-Ф180, gear steel is soft, the material diameter is large, can’t use the bar cutting machine, it is recommended to use disc saw or band saw.

|

|

Productivity |

Degree of |

Aut Quantity |

Labor Cost |

Equipment |

|

Band Sawing Machine |

high |

high |

good |

low |

high |

|

Circular Saw |

low |

low |

good |

high |

low |

Making blank:The heating of the bar need to upsetting, punching, adjusting height, to ensure that the expansion ratio in a reasonable range, the making blank is the most important step in the whole process, commonly used three kinds of equipment,

|

|

Productivity |

Quality of |

Labor Cost |

Degree of |

Equipment |

|

Pneumatic Hammer Making Blank |

low |

general |

high |

low |

low |

|

Special Hydraulic Forging Press |

high |

high |

low |

high |

medium

|

|

Mechanical Forging Press |

high |

high |

medium

|

high |

high |

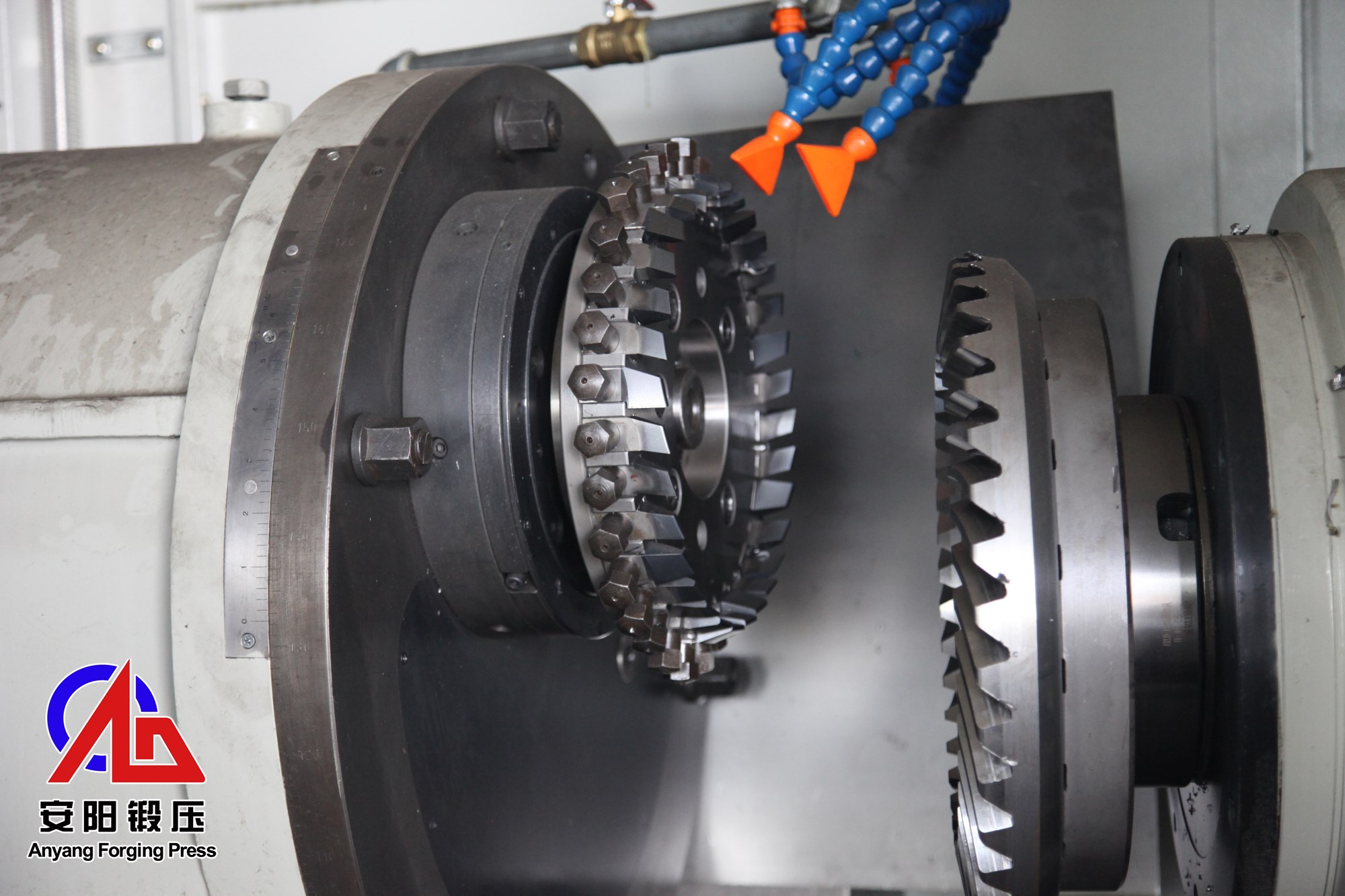

Final Forging: Final forging after rolling ring, we can use forging hammer or screw press. at present, forging hammer have full hydraulic forging hammer and CNC forging hammer, screw presses have friction presses and electric screw presses.

|

|

Productivity |

Product Quality |

Degree of |

Equipment |

Product Quality |

|

Forging Hammer |

High |

good |

general |

medium |

good |

|

Electric Screw Press |

High |

good |

good |

High |

good |

Basin Gear Forging Line Feasibility to Achieve Automation

Reasonable matching equipment, can be fully or part of the realization of automation. Recommended configuration for automated production line is as follows:

Medium frequency induction heating furnace - special hydraulic forging press making blank / mechanical forging press making blank - rolling ring machine making ring - electric screw press final forging

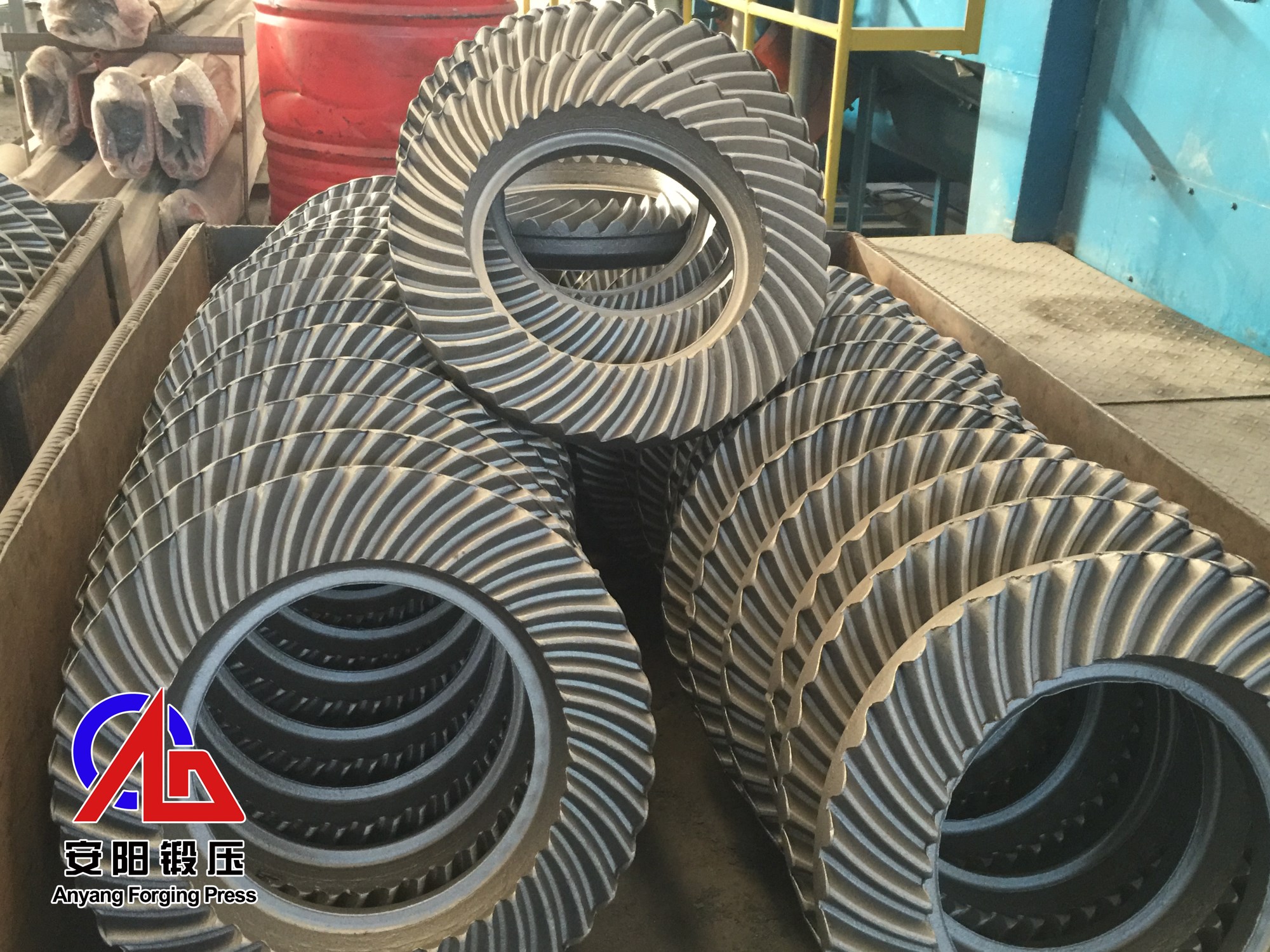

Basin Gear Forging Line Engineering Case

forging line