What causes hot forging scale?

In the forging production process, the metal blank need to be heated to high temperature firstly, steel react with oxygen on the billet surface, oxidation occurs during the heating process, which will generate a layer of metal scale or slag. If it can’t be removed before forging process, these scale or slage will be press into the steel. As the hot forging scale is made of simply Fe3O4, black iron oxide, which not only affect the appearance quality, but also reduce local strength, if these hot forging scale appearing on machined parts of forging, it will also reduce machining allowances, and have the risk of processing scrap.

Why should remove the hot metal scale?

- Tapping on the forging equipment and using metal deformation to remove the scale can help reduce the production pace;

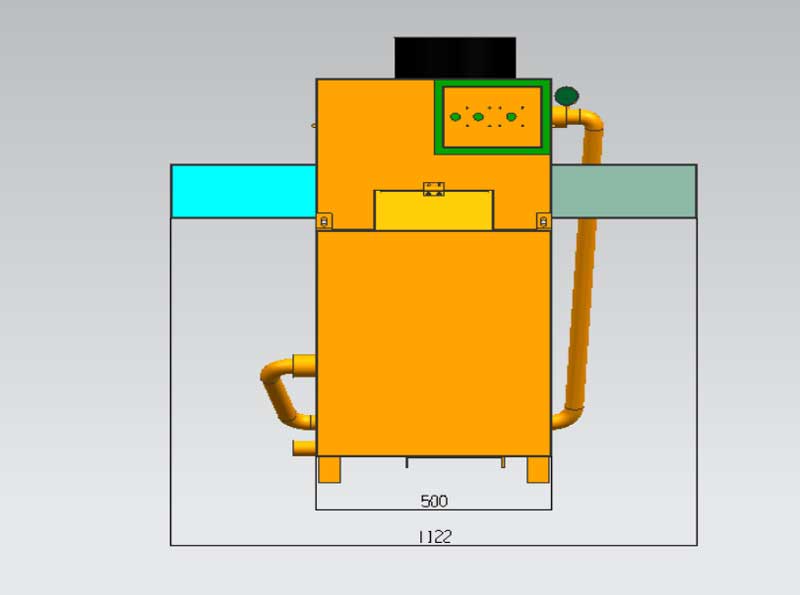

- Scale removal device. The scale generated on billet surface during heating process is removed before forging production.The use of position adjustment bolts and scraper replacement can be widely adapted to various shapes and sizes of blank.In addition, the blank of different materials can be removed by replacing the preset torsion spring.

Advantages of hot forging scale removal device

- Stable equipment performance;

- Long service life;

- Reduce the labor intensity of operator;

- Good effect of removing scale and fast speed;

- Automation working, and connecting with forging production line is easy.

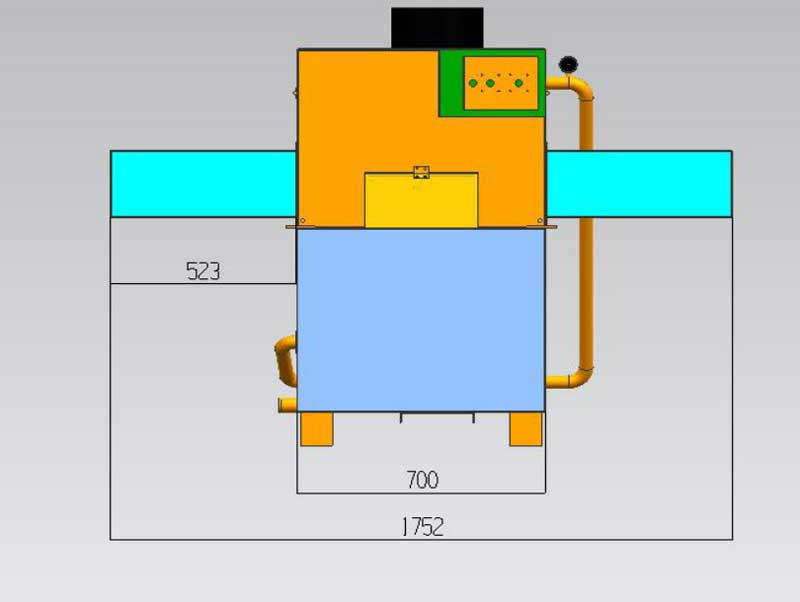

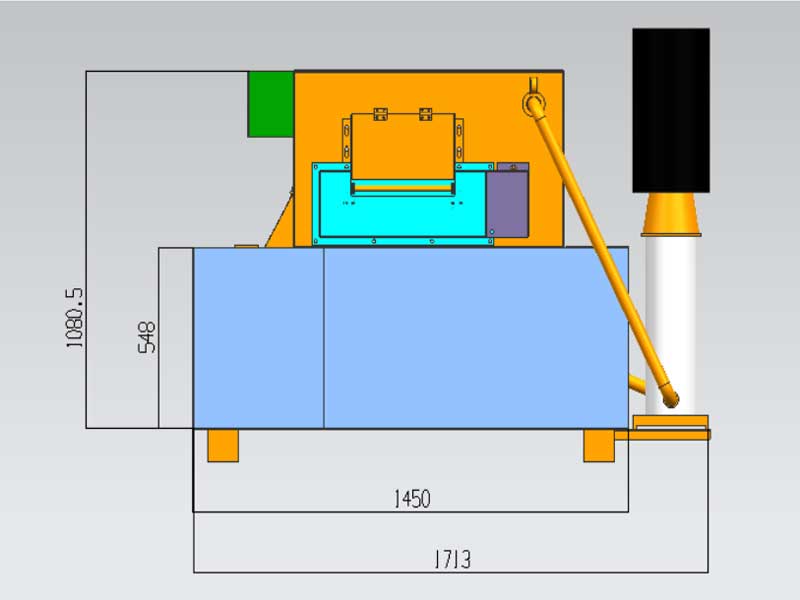

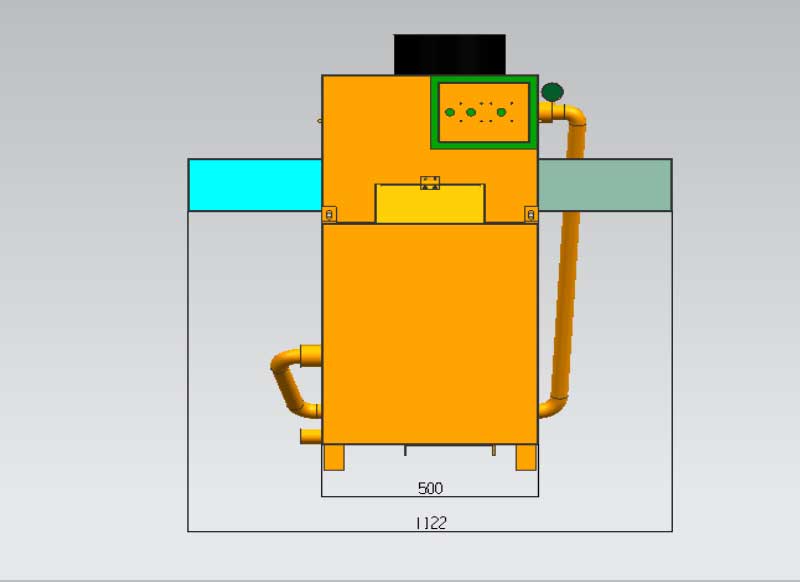

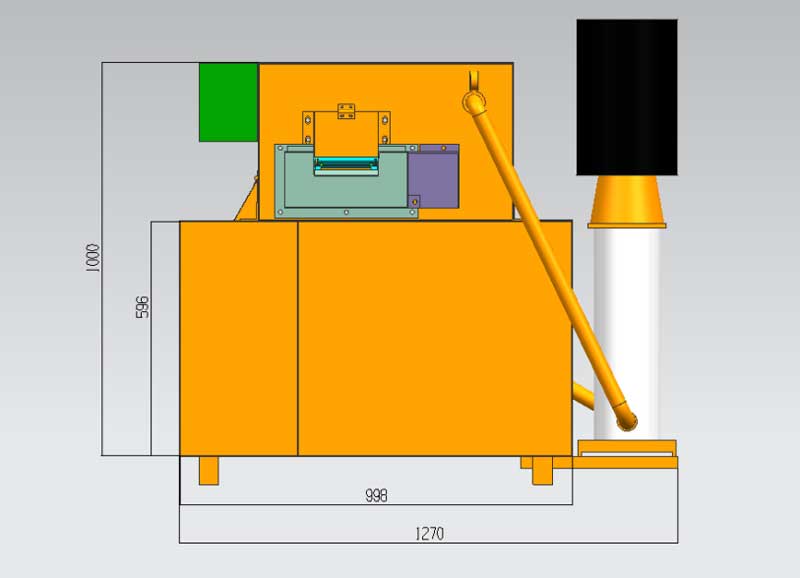

Metal Scale Removal Machine Parameter