What is Claw Pole?

Claw pole is an important component of generator. Its material, heat treatment and working face size will have an important impact on the performance of generator. Therefore, claw pole forging requires not only high forging technology, but also high forging equipment. Only in this way can high quality claw pole be forged.

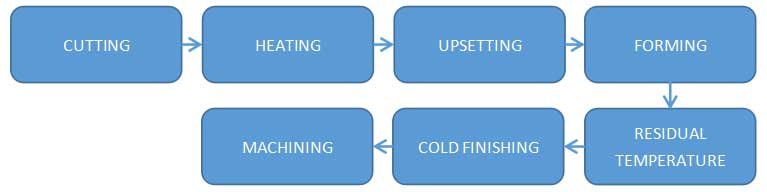

Process of Claw Pole forging line

Cutting --- Heating --- Upsetting --- Forming --- Residual temperature annealing--- Cold finishing --- Machining

Flow Chart fo Claw pole production

Claw pole forging production line Process analysis

The process has the following characteristics:

- Mold shape: Due to positive extrusion, convex die adopt profiled die, compared with the anti-extrusion convex die, not only low processing costs, but significantly increase in life. The concave die is an integral cavity with six vertical claws inside, so there is no burrs, and the size of the claws on both sides can be made to meet the requirements of the product. In actual work, the concave die needs to be made into a split die and add prestressed ring structure , so as to meet their working conditions and improve die life.

- Forming load: claw tip in the extrusion process once complete shape, which requires great force, and will seriously affect the die life. The new process will deepen the vertical pawl cavity of the concave die and set the exhaust hole, which is equivalent to setting the compensation space at the tip of claw, this not only reduces the strict requirements of the cutting accuracy, but greatly reduces the forming load and improve the die life.

- Impact of oxide skin: In actual production process, the residue at the bottom of the concave die such as oxide skin is difficult to completely clean up , when using of vertical claw cavity is not deepened concave die, the actual production process due to oxide and other residues are not completely clean up lead to the claw tip is not full, resulting in waste; when the use of vertical paw cavity deepened concave die, the claws dissatisfaction filed can be avoided, improve product qualification rate.

- No flash: Adopt closed type forging extrusion forming, will not produce even skin and flash, no trimming process.

- Cold finishing: As in the positive extrusion process, the claw pole has been substantially formed, cold finishing only need to correct the shape of after the cold shrinkage claw pole, the degree of deformation is very small, no need phosphating saponification process, equipment requirements are low.

Install special hydraulic molds and control systems on electric screw presses, realize occlusion forging, precision forging claw pole.

Claw Pole Forging Videos

Claw pole forging production line video