Process of Bearing Forging

-

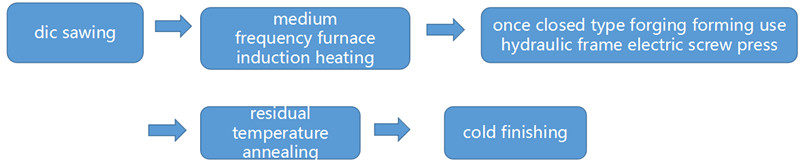

Single forging line process

Billet shearing machine ( warm cutting, hot cutting, sawing cutting ) → medium frequency induction furnace heating → forging ( press upsetting, squeeze half hole, punching and height sizing) → ring rolling machine rolling → finishing.

-

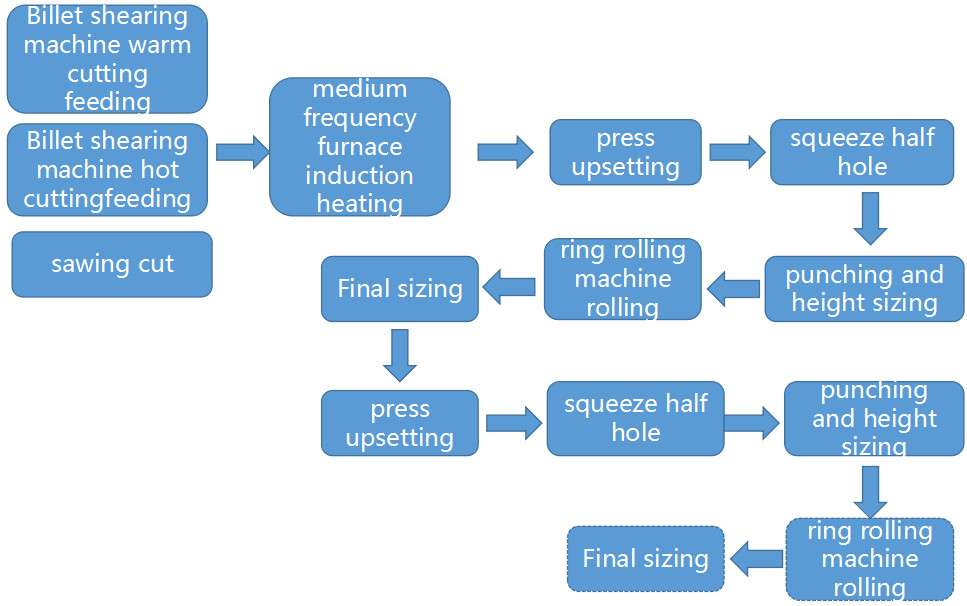

Combination forging line process

The combination line process is essentially two production lines, the first line produces bearing outer ring, the second line produces the bearing inner ring, when the outer ring is forged, the punched core is used to forge the inner ring, there is no heating furnace on the second line, according to the process requirements to determine whether requires for rolling ring and final sizing.

Flow diagram of automatic forging

- Flow diagram of single forging line

2.Technical diagram of combination forging line

Bearing forging production line Process analysis

- Feeding: there are three kinds of cutting methods for bearing steel: warm cutting, hot cutting and saw cutting. Direct forging after hot shearing, twice heating requires after warm shearing, sawing is a regular cutting method, but usually the bearing ring forging is mass production, sawing efficiency is low.

- Forging: forging presses are common presses and multi-station presses, forging on an ordinary press is usually done by manual forging, can also be modernized into automation, multi - station presses with automatic walking beam can realize automatic production of bearing ring.

- Rolling ring: ring rolling machine include CNC ring rolling machine and ordinary ring rolling machine, used for automatic or manual lines.

- Final sizing: final sizing is to improve the accuracy of the ring, cost savings, according to the process needs to select the process.

Bearing rings forging line videos:

Automatic forging production line for bearings

how to forge bearing rings automaticly

high efficency hot forge bear rings video