How to Choose the Right Screw Press for Forging Factory?

2020-04-22 09:59:26Screw forging press is a kind of mechanical press. More than 500 years ago, people began to use the interaction of screw and nut to generate pressure to serve human life, such as to press vegetable oil and small non-ferrous metal products. This kind of press is used in a limited range because of the pressure produced by manually moving the flywheel. During the first industrial revolution, human invented the steam engine. More than 150 years ago, the mechanical predecessors invented the friction press, that is, the power of the steam engine was driven by friction to work the screw forging press, which brought the opportunity for the screw press to serve human industrial production.

Up to now, human beings have tried many different power ways to drive screw forging press, the mainstream of which are friction screw forging press, hydraulic screw forging press, clutch electric screw forging press, direct drive screw press with integrated motor screw, gear / belt driven screw press, etc. Since there are so many different screw forging presses, as forging users, what kind of screw forging press is most suitable for them?

Types and Differences of Screw Forging Press

- Friction screw forging press has low cost, large working noise and low energy utilization ratio;

- Hydraulic screw press needs complex hydraulic system by hydraulically driving flywheel movement, which has high cost and complex maintenance;

- Clutch electric screw press is also called high-energy clutch screw forging press, which adopts mechanical hydraulic hybrid power, with more complex design, the highest cost and the most complex and expensive maintenance cost.

- The special motor equipped with the motor screw integrated direct drive screw press is easy to be damaged during forging vibration and must be repaired by professional personnel. The use cost is high and only suitable for small tonnage presses.

- The screw press driven by gear / belt is commonly known as the electric screw press, which is characterized by simple structure, high efficiency, energy saving and low cost. It is the most popular design in the screw press industry.

Electric Screw Forging Press from Anyang Forging Press

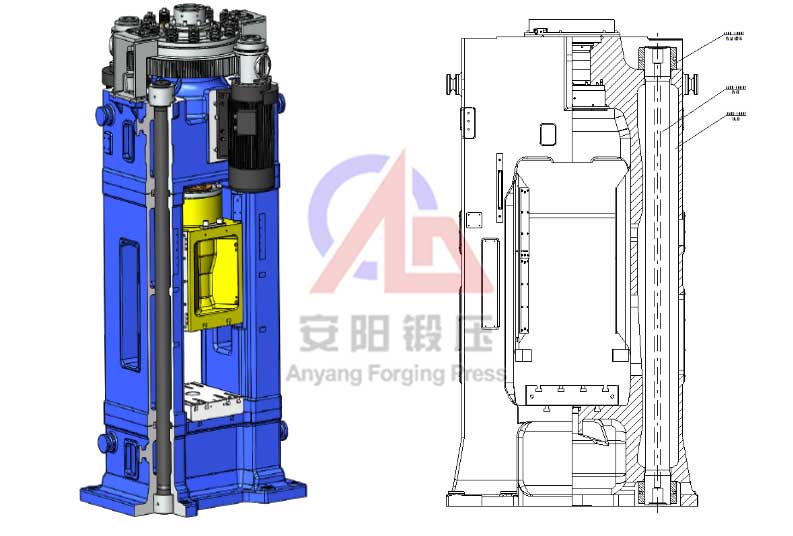

The electric screw press developed by Anyang forging press is driven by gears, which integrates the advantages of various of screw forging presses and brings the advantages of the electric screw press to the extreme. Compared with friction screw forging press, it can save more than 30% energy, and its selling price is far lower than that of high-energy screw press.

Advantages of Anyang Electric Screw Forging Press

Through technical design innovation, the advantages of electric screw press with Anyang forging characteristics are created:

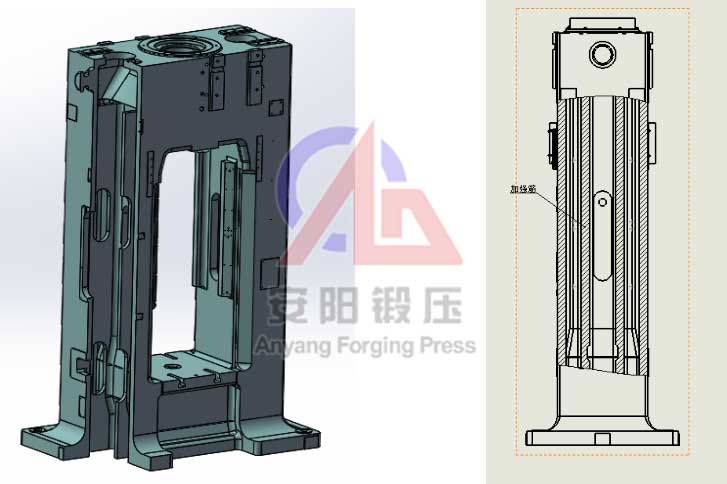

- Improve the column structure, improve the anti overload capacity of the column, and expand the use range of the electric screw forging press. Part of the energy output from the electric screw forging press is used for forging forming, and part of it is converted into the elastic energy of the column. When the effective energy provided by the flywheel is far greater than the deformation energy actually required by the forging, most of this energy will be converted into the elastic load of the column. Once the elastic load exceeds the allowable value, the life of the column will be greatly shortened, and the column will be broken in serious cases. The series of electric screw presses developed by Anyang Forging Press have all optimized the design of the column. In the interior of the column, especially in the place where the guide rail is stressed, the normal lengthened rib plate is added. In the press of over 1000 tons (including 1000 tons), the prestressed tension bar is added. The extra energy is borne by the tension bar, which greatly improves the reliability of the column and the whole machine. The maximum allowable load of the electric screw forging press is 1.6 times of the nominal pressure.

- Various ways are adopted to improve the anti bias load capacity. The electric screw forging press of Anyang Forging Press adopts the guiding form of long slide block and long guide rail, which has high guiding accuracy and greatly improves the anti eccentric load capacity. And according to the needs of users, special design can meet the needs of multimode cavity users.

- Can customize all kinds of forging automation production line, provide a package of turnkey project. Anyang Forging Press has rich experience in hot forging production line design. According to the forging requirements of customers, it provides customers with the turnkey project of forging process design, forging equipment manufacturing, forging automation design and other services.