make gear Technological process

Cylinda-shaped gear and the forges with similar shape can follow this process.Gear forging can be forged by open type forging or closed type forging.

-

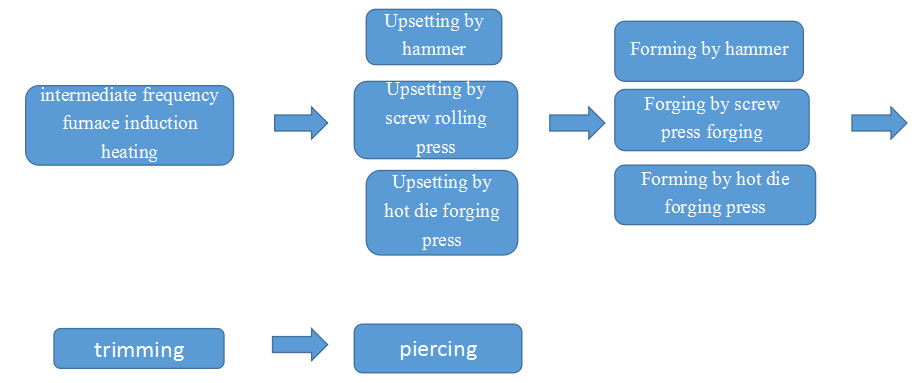

Open type forging process

Cutting--heating--upsetting the diameter close to the final shape--final forging--trimming--punching.

-

Closed type forging process

Cutting--heating--upsetting--final forging--punching.

make gear Process flow chart

make gear Technology analysis

The hammer, screw press and hot die forging press can all make up the gear production line. As gear diameter increasing, the equipment tonnage rising, but the investment differs much.

|

|

The price for small size gear |

The price for medium size gear |

The price for large size gear |

|

Hammer |

medium |

Similar with screw press |

Lower than screw press |

|

Screw press |

low |

Similar with hammer |

Higher than hammer |

|

Hot die forging press |

high |

Very high |

Much higher than hammer and screw press |

Automation

It’s easier for screw press and hot die forging press to achieve automation.

The Project case

Gear forging line

Gear forging line

Gear forging line