CNC Double-Acting Forging Hammer VS Electric Direct Drive Screw Press- Differences & Comparison

2020-06-13 10:03:20

CNC double-acting die forging hammers and electric direct drive screw presses are already the two core die forging equipment commonly used in the die forging industry. But if new die forging projects should choose die forging hammers? Or choose an electric screw press? I will make the following comparative analysis for you on these two die forging equipment, see the comparison table.

| Group |

Equipment |

Blow Energy (kj) |

Strike Force (ton) |

Forging Accuracy |

Anti-eccentric Load |

Shake |

Energy Control Method |

Price |

Foundation |

Die Cost |

|

| 1 |

25kj CNC Die Hammer |

25 | 1000 | High | High | Big |

CNC and Accurate |

1 |

Shock-absorbing Foundation |

The press die has no dovetail, no need to consider the bearing surface, the cost is usually 60% of the forging hammer die |

|

|

400 ton Electric Screw Press |

40 | 640 | Common | Common | Small |

CNC but Common |

0.56 |

Ordinary Foundation |

|||

| 2 |

31.5kj CNC Die Hammer |

31.5 | 1300 | High | High | Big |

CNC and Accurate |

1 |

Shock-absorbing Foundation |

||

|

630 ton Electric Screw Press |

80 | 1000 | Common | Common | Small |

CNC but Common |

0.77 |

Ordinary Foundation |

|||

| 3 |

50kj CNC Die Hammer |

50 | 2000 | High | High | Big |

CNC and Accurate |

1 |

Shock-absorbing Foundation |

||

|

1000 ton Electric Screw Press |

160 | 1600 | Common | Common | Small |

CNC but Common |

0.73 |

Ordinary Foundation |

|||

| 4 |

80kj CNC Die Hammer |

80 | 3150 | High | High | Big |

CNC and Accurate |

1 |

Shock-absorbing Foundation |

||

|

1600 ton Electric Screw Press |

280 | 2500 | Common | Common | Small |

CNC but Common |

0.88 |

Ordinary Foundation |

|||

| 5 |

125kj CNC Die Hammer |

125 | 5000 | High | High | Big |

CNC and Accurate |

1 |

Shock-absorbing Foundation |

||

|

2500 ton Electric Screw Press |

500 | 4000 | Common | Common | Small |

CNC but Common |

1.2 |

Ordinary Foundation |

|||

|

The forging capabilities of the two devices in the same group are basically the same. For the forgings with small deformation, the efficiency of the CNC double-acting die forging hammer is higher than that of the electric direct drive screw press. For the forgings with large deformation, the efficiency of the electric screw press is higher than the CNC die forging hammer. |

|||||||||||

According to the above table, no one of the two die forging equipment is absolutely better than the other one, but it is more suitable for forming different forgings.

Characteristic of CNC double-acting die forging hammer

Forging hammers are known as universal forging equipment in the field of forging, because their energy can be superimposed to create them with the characteristics of small hammers that can do huge forging work. Especially suitable for small batch and multi-variety production.

Advantages and disadvantges of CNC double-acting die forging hammer

- The CNC double-acting die forging hammers are designed with X-shaped guide rails, and the guide columns are made of solid cast steel.

- The anti-eccentric load capacity is particularly strong, which can realize multi-cavity forging.

- The impact energy can be digitally controlled and the deviation is ≤±1.5%, which means that the CNC die forging hammer has very little excess energy acting on the mold, and the contact time of the upper and lower dies is extremely short, so the forging die life of the CNC die forging hammer is 2- 3 times.

- The ram speed of CNC double-acting die hammer forging can reach 6M/S, so the CNC die forging hammer is especially suitable for forging thin-walled forgings, which can be quickly formed before its temperature is lowered.

- Equipped with shock absorbers can effectively reduce the vibration of more than 90%.

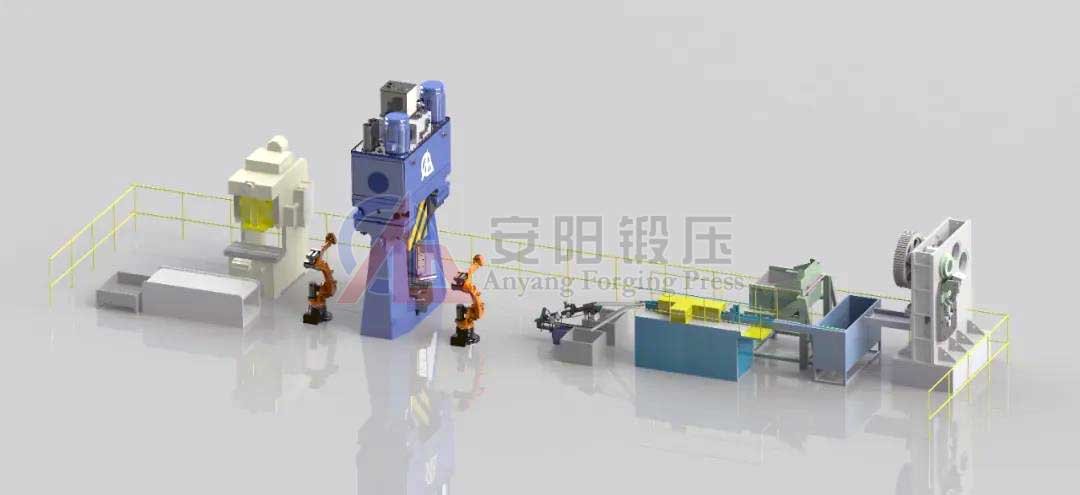

- Cooperating with robots can realize fully automatic forging production line.

- Special shock-absorbing foundations are needed, and the foundation cost will be higher than that of electric screw presses.

automatic forging line with double acting die hammer

Characteristic of electric direct drive screw press

The electric direct drive screw press is a new type of die forging equipment that has evolved through the optimization of the transmission system on the basis of the principle of the friction press, that is, the original friction drive has been replaced by gears, belts or motors (see several screw presses for details). Working principle and comparative analysis), taking into account the dual attributes of hammer and press, with small investment (especially models below 1600 tons), quick results and flexible production organization. This is why electric screw presses are more popular in the die forging industry for several years.

Advantages and disadvantages of electric direct drive screw press

- Compared with the die forging hammers and hot die forging presses of the same capacity, the tonne of electric direct drive screw presses below 1600 tons have obvious cost advantages.

- Due to its structural characteristics, the guide transmission system must reserve a certain gap of about 1mm, otherwise the slider will be stuck during the forging process, so the clamping accuracy of the electric screw is not as high as that of the CNC die forging hammer.

- The gravity of the final forging die cavity must coincide with the center of the screw, because its forging force will be attenuated by the geometric multiple of the center of the screw, so the electric screw press is not suitable for multi-cavity forging, otherwise it will be greatly guided as soon as possible. The system is worn down and even the slider is stuck.

- Electric screw presses control the blow energy and slider movement direction by controlling the speed and direction of the motor, but due to the huge inertia of the transmission system and the error of the electronic control system, the deviation of the blow energy can only be controlled at about 15%. It is very different from the 1.5% of the CNC die forging hammer, which is also one of the main reasons for the die life of the CNC die forging hammer.

- However, because the press die does not have a dovetail and the bearing surface is not considered, the manufacturing cost of the electric screw die, generally, it is only about 60% of the CNC hammer mold, and the overall mold cost is basically the same as that of the CNC hammer.

- Compared with the die forging hammer, which is suitable for thin-walled forgings, the electric screw press is particularly suitable for forgings with large deformation such as local long rod forgings, pier thickening, punching, and extrusion.

- When the electric direct drive screw press is working, the amplitude of the lower die working surface is very small, which creates favorable conditions for the robot to grip the forgings. In this regard, the electric screw press unit is much easier to build an automated forging line than the CNC double-acting die forging hammer.

forging automation line with screw direct drive press

Which die forging equipment should I choose?

- CNC double-acting forging hammer is suitable for the thin wall forgings with small-batch and multi-varieties production needs.

- Electric direct drive screw press is suitable for the long size forging, and it is more suitable fore upsetting, drawing-out, punching than die hammer.

- Compared with the die forging hammers and hot die forging presses of the same capacity, the electric screw presses below 1600 tons have obvious price advantages.

- A small tonnage CNC die forging hammer can forge huge forging blank because of its characteristic of energy stack, but electric screw press has strict tonnage ratio requirements.

- Electric screw press is more environmentally friendly than double-acting die forging hammer, low noise and low vibration.

Anyway, whatever the CNC double-acting forging hammer and electric drive screw press have advantages and disadvantages, we should choose a suitable one according to our forging conditions. Anyang Forging Press can design and manufacture both of CNC forging hammer and electric screw press, customized solution is available. If you are wondering which kind of forging machine should you choose, please contact us, we can ready to help you!