What is Hot Punching Process?

T Pipe Fitting Hot Punching Die

Irregular Fittings Hot Punching Tool Dies

The compare between hot punching process and hot extrusion process

The features of hot punching process

- Hot punching process is a process of forming metal material by hot stamping, belonging to the field of thermal processing. Firstly, put the heated metal blank into mold, and then the stamping action caused by press makes plastic deformation occur in it, thereby pressed part with various shapes and good mechanical properties can be made.

- The metal billet is deformed by heating and extrusion, which eliminates defects of original material caused by casting and drawing. The deformed metal fiber structure is distributed from inside to outside in a continuous state, which improves the mechanical properties of hot punched part.

- After the metal material heated and extruded, internal crystal grains are refined, the density of the metal is enhanced, and the surface corrosion resistance is improved.

- The hot punching process can extrude piece of any shape especially advantageous for the small rod forging, deep hole cup forging, inner and outer diameter upper teeth, the toothed shape, the upper cup lower rod forging and the forging of small middle and four large faces. The deformed metal is in a three-direction stress state due to the extrusion, so it’s easy to process the difficult-to-deformed precious metal.

- During the extrusion, the metal blank is put into the die and material storage cavity firstly, and then the blank metal is squeezed into the die cavity to form under the pressure of upper die. This forming method seems to be similar to injection mold, but the flow of the extruded metal is not liquid, so its flow performance is worse than that of injection mold.Compahot with the forging die, the metal deformation rate of the hot stamping die is higher, and fiber continuous structure of the metal shape of hot stamping die is much better than that of injection die and forging die.

- The hot punching process has good adaptability and can be widely used. Actually the hot punching process is similar to precision forging, but the requirements to the die and press are much simpler than precision forging. As long as little correction to the mold or machine, the extrusion can be realized on general pressure machine.

- Hot punching process is one of the processing methods of metal parts without cutting, which can save a lot of metal raw materials.It not only has high production efficiency, but also saves labor and materials. It can improve economic efficiency and product quality obviously.

Advantages of hot punching process

- Forming is not limited by the external shape of product parts;

- Common equipment is used in production, which is easy to put into production and suitable for small and medium-sized enterprises;

- High productivity, suitable for mass production;

- As a result of use of core-pulling device, the interior of part pressed out is hollow, unlike the solid interior of forging die processed out, and generally the rough edge thickness of small hot stamping die is about 0.5mm, and forging die part is generally more than 2mm, so the material utilization rate of hot punching process is higher.

- hot punching press is a process with less cutting, the roughness of surface is close to mold, and size accuracy can reach 6-7 level, so its amount of mechanical cutting is very small;

- The mechanical properties of the hot punching process are good, because after it the metal blanks are heated, squeezed and cooled, the metal structure changes, eliminating the defects caused by casting or drawing. The internal crystal structure is linear from inside to outside, which improves the mechanical properties of the piece.

- After hot punching process, the internal grain of the metal is refined, which enhances the density and improves anti-corrosion ability of parts;

- Suitable for all kinds of non-ferrous or black metal processing.

Copper Hollow Parts Hot Punching Dies

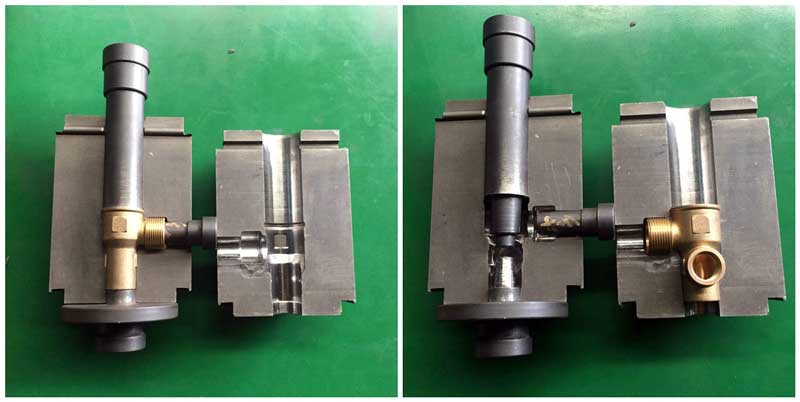

Valve Hot Punching Die