Control arm forging production line Production process

-

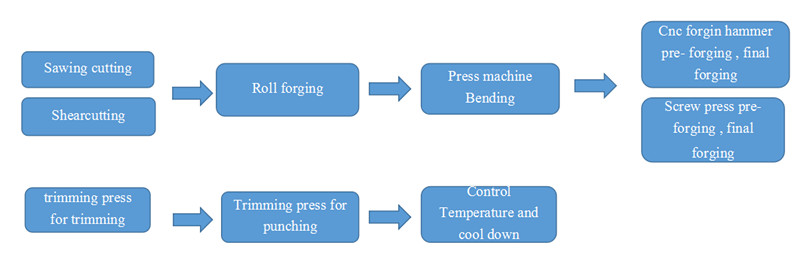

No1 process

Sawing or bar shear bed cutting, medium frequency induction furnace heating, roll forging machine Separating material, bed bending, CNC hammer final forging, precision forging, press machine trimming , press punching, control temperature and cool down

-

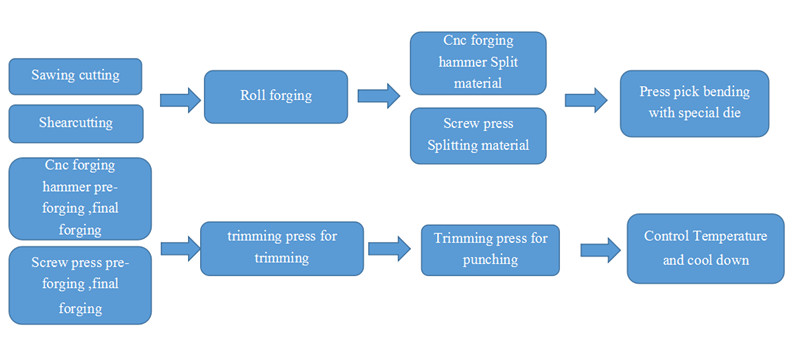

No2 process

Sawing or bar shear bed cutting, medium frequency induction furnace heating, roll forging machine material, CNC hammer or electric screw press splitting material, press trimming, with special molds on the press bending, CNC hammer or electric Screw press on the final forging. Press cutting edge, press punching, temperature control cooling

Process flow chart

- No1 process

- No2 process

Control arm forging production line Process analysis

The first Process is generally used in the production process that the top of the middle control arm don’t bulb

Second Process is generally used for the forging of the control arm with a large concave at the middle top.

The forging equipment uses either a CNC hammer or an electric screw press, and there is no obvious difference between the two types of equipment.

Control arm forging production line Project case

Control arm forging production line

Control arm forging production line