How to design Vibration Absorb System for Forging Hammer and Press Foundation?

2019-09-26 15:07:54Why is Vibration Absorb Important for Forging Machine?

The forging machine will produce vibration and noise when punching and forging the workpiece. Noise transmitted directly through the air is called primary noise, which is usually treated by a sound insulation room or a sound barrier. Another kind of noise is that the vibration is transmitted to the surroundings through the equipment foundation, which causes the vibration of the floor and the wall of the building, and produces structural noise, which we call secondary noise, to control this kind of noise, it is necessary to install vibration absorber or elastic vibration absorb foundation.

In the actual production layout, in order to make more effective use of workshop space and improve production efficiency, the distance between forging equipment and measuring instruments is very small. The vibration produced by forging equipment is very large, which seriously affects the surrounding processing equipment and measuring instruments. At the same time, it has a serious impact on the lives of the surrounding residents and the production of the factory. Therefore, it is necessary to absorb vibration.

How to Choose Vibration Absorber for Different Forging Machine?

According to different forging machine, the vibration control system is different. It should be designed according to the machine capacity, working environment, running method, etc. With more than 64 years experiences in forging machine manufacturing and installation, Anyang Forging Press provide you the following advice to choose vibration absorber for your forging machine.

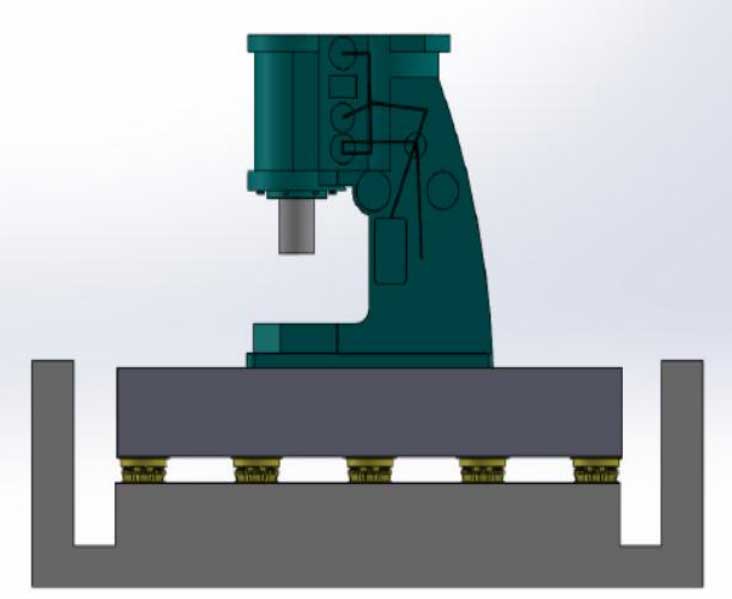

Vibration Absorber for Small and Medium Forging Presses

Small and medium-sized press can generally place vibration absorber directly at the foot, without the need for a separate foundation block, double-point press can directly place vibration absorber under the foot. The single-point press can place vibration absorber directly under the sole foot, or steel plate under the sole foot, and vibration absorber under the steel plate to increase stability and reduce the amplitude of shaking.

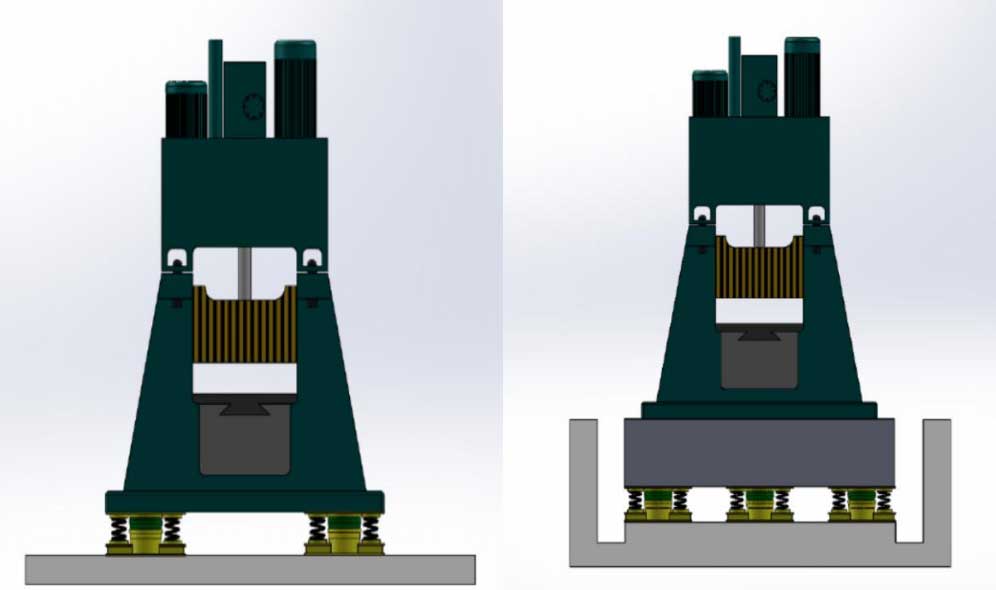

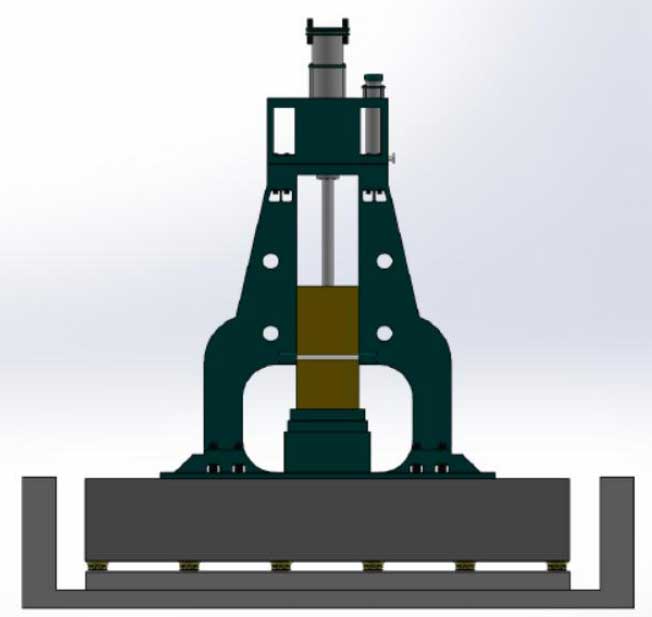

Vibration Absorb System for Forging Hammer

In the process of forging hammer, a part of energy makes metal shape, and the remaining part of energy will spread to the ground, causing great vibration. At the same time, because more and more high-precision test equipment and machine tools are installed around the hammer, it makes the installation of spring absorber and viscous damper at the bottom of the hammer become forging. International standards for the industry. Spring direct support is the standard solution for all die forging hammers. Only for counter blow hammers and other hammers that allow only small displacements, concrete foundation blocks need to be added as additional mass, as shown in the figure.

vibration absorber foundation degign for electric screw press

vibration absorber degign for closed die forging hammer

vibration absorber foundation degign for open die forging hammer

vibration absorber degign for pneumatic forging hammer

Selection Method of Spring Vibration Absorber

- If the forging equipment base itself has enough stiffness and quality, it can be placed directly on the absorber, otherwise, a steel plate, steel frame or concrete base with enough stiffness and quality should be designed.

- According to the size of the bottom of the forging machine and the number of the foot, the location and number of spring absorbers are determined. The absorber is placed on both sides of the bottom of the forging machine. The distance between the adjacent absorbers should be 1-2 meters. The working load and rated load of the absorber are calculated from the total weight of the machine and the base block and the number of absorbers. The working load does not exceed 80% of the rated load.

- According to the main disturbance rotation N and frequency fe=n/60 of the equipment, the vertical natural frequency f0 of the absorb system is determined. The smaller the ratio of F0 to fe/3f0, the higher the absorb efficiency.

- According to the rated load F and the vertical natural frequency f0 of vibration absorb, the appropriate type of vibration absorber is selected.

- According to the rigidity of the absorber, the vertical compression and natural frequency f0 = 5/delta are checked. In the formula, delta is the spring compression, in centimeters.

- Check and adjust the arrangement of the absorbers so that the center of support force of all absorbers coincides with the center of gravity of load of the machine and foundation blocks, and the machine does not deflect in theoretical calculation. The tilt during installation can be leveled by adjusting the position of the absorber and the leveling steel plate.

Damping shock absorber for forging machine

Who can Help You Design Vibration Control System for Your Forging Machine?

Anyang Forging Press is the biggest forging machine manufacturer in China since 1956, our forging hammer and press have been exported to more than 64 countries, such as America, Australia, England, Russia, Vietnam, Japan, India, etc.

After you ordered our forging machine, we will provide complete custom forging machine installation service for you, including foundation design and vibration control system design and built. If your equipment installation space is limited, if you forging equipment shock absorption requirements are strict. If your workshop layout is complex, please contact us, we will provide you with the most professional forging equipment and foundation shock absorption solutions. Anyang Forging Press is your trust forging machine manufacturer!