An Efficient Steel Ball Forging Process In The Steel Ball Making Machine

2019-03-30 16:55:10Wear-resistant steel ball, also known as wear-resistant medium for grinding machine, is a consumable, its main purpose is to grind the material to make the material finer to meet the standard of use. The Wear-resistant steel ball is mainly used in mines, power plants, cement plants, steel plants, silica sand plants, coal chemical industries, etc. The annual consumption of steel balls in the world is between 30 million and 50 million tons, of which the consumption of Chinese steel balls is between 3 million and 5 million tons, is a major consumer of steel balls.

The steel ball making process can be divided into three types: forged steel balls, cast steel balls and hot rolled steel balls.

Forged steel ball

After the round steel is cut, it is forged with an air hammer. The wear resistance of the forged steel ball is closely related to the used material of the round steel and the quality of the impurities or round steel.

The main material of forged steel ball: mostly made of high manganese steel (50Mn and 60Mn or 65Mn). At present, the wear resistance of 75MnCr is comparable to that of high-chromium balls.

Advantages of forged steel ball

- The breaking rate is less than 1%

- The wear resistance is good

- The price is cheap, the cost performance is high

Disadvantage of forged steel ball

- The production efficiency is low.

steel ball forging line

cast steel ball

Chromium alloy is the main component of cast steel ball. Its strength and density are lower than that of forged steel ball. The breaking rate is much higher than other steel balls. According to the level of chromium content, the wear-resistant ball can be pided into the following types:

- The chromium content is 1%-3% and the hardness is HRC≥45. This kind of wear-resistant steel ball is called low-chromium alloy cast ball, and the low-chromium ball is produced by medium-frequency electric furnace melting, metal mold or sand casting. Its performance is suitable for some metallurgical mines, slag and other industries where the grinding precision is not high and the wear and tear is not high.

- The chromium content of 7%-10% and the hardness HRC≥50 are medium chromium alloy cast balls, and the performance is higher than that of the multi-alloy steel balls.

- Chromium content ≥10%-14%, hardness HRC≥58, high chromium alloy casting ball, is a wear-resistant ball with high utilization rate and good wear resistance in the cement industry. It has a wide application range, but it is expensive. The reason for the replacement of forged products caused the market to gradually decline.

- The chromium content exceeds 14% and the hardness HRC ≥ 58. This is a special high-chromium steel ball, which is suitable for industries with fine grinding and high wear and tear. Of course, the price is also high, and the cost performance is lower than that of high-chromium balls.

casting operation is dangerous, the internal structure is poor, the efficiency is lower

Hot rolled steel ball

The hot-rolled steel ball is produced in the rotary cutting production line. It has risen rapidly in recent years. It not only has high production efficiency but also high degree of automation, high material utilization rate, stable steel ball size and quality, and excellent cost performance, but the quality is not as good as forged steel ball.

steel ball hot rolling line

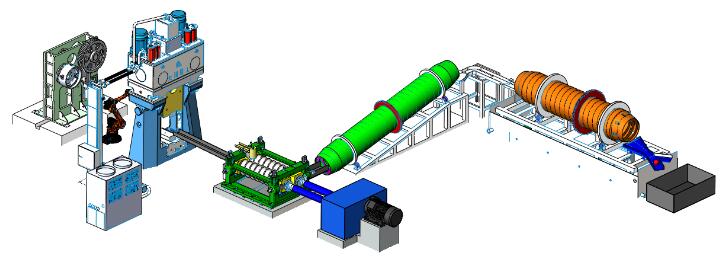

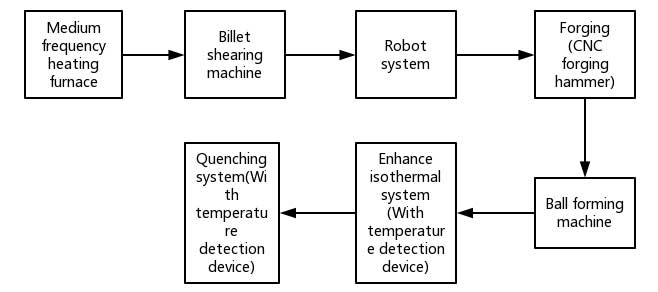

Steel ball forging-rolling production line

Anyang Forging Press recently developed a CNC steel ball forging-rolling line for a steel ball production customer in Anshan, effectively taking into account the advantages of good quality of forged steel balls and high production efficiency of rolled steel balls. Billet hot shearing shears the bar, using a forging manipulator to transfer the material to the CNC die forging hammer, pre-forge them into balls. The use of die forging ensures the forging ratio of the forgings to ensure the quality of the steel ball and greatly improves the forging efficiency. Then, the forged steel ball is rounded by a roller machine similar to the principle of the cross mill to ensure the roundness of the steel ball is perfect. Generally, the cross-rolling mill can only roll steel balls of less than 120 mm, however the steel ball size that can be produced theoretically by the forging-rolling steel ball process does not have an upper limit. This steel ball production process is bound to become a new trend leading the production of steel balls.

Process of Steel Ball CNC Forging-Rolling Line

steel ball forging hammer machine

rolling machine for steel ball