Advantages and Disadvantages of Screw Type Forging Press

2019-10-09 09:25:42In the middle and small batches of the forging workshop and some special production lines for mass forging production, screw type forging press is widely used. According to the different driving methods, the screw forging press mainly includes three types: friction screw forging press, electric screw forging press and hydraulic screw forging press. At present, most of the friction presses with nominal pressures of 1000~1600kN are used in China. In addition, large-sized screw presses such as friction presses with a nominal pressure of 25000kN, hydraulic screw presses of 40000kN and electric screw presses of 6300kN are also used, which have been applied in production.

What's the Differences between Screw Type Forging Press and Forging Hammer?

Compared with the die forging hammer, the screw type forging press has the advantages of low equipment cost, low requirements on the plant and foundation, less vibration and noise during operation, lower energy consumption and mold cost, and better working conditions. In addition, the screw forging press has forging ejector pin device, which can perform some processes such as forging long rods, extrusion cylinders, closed die forging and precision forging which are difficult to complete on the die forging hammer. However, ordinary screw presses have a lower number of strokes and are less capable of withstanding a bias load, and generally only perform single-turn molds. The blanking process of complex forgings needs to be completed with other equipment, and the productivity is not as high as that of the die forging hammer.

Comparison of Electric Screw Forging Press and Friction Forging Press

The same point

The rotation of the screw is used to drive the up and down movement of the slider, which has a simple structure, a low maintenance cost, and a small vibration.

Differences between Electric Screw Forging Press and Friction Forging Press

- The friction screw forging press has a simple structure and low price. However, the transmission efficiency is low, the slider is about 0.65 when going down, and the slider returning is about 0.35. Friction belts are prone to wear and need to be replaced frequently. Strike energy is not easy to control accurately.

- The friction press relies on the manual operation of the workers, the labor intensity is large, the quality of the forgings is not easy to control, and the quality of the workers is relatively high.

- The electric impact of the electric screw forging press can be precisely controlled, and the forging forming tolerance is small. The operation ability of the workers is not high. Just set the hitting energy required for forging forming, and the computer will control the strike process without manual intervention.

- Because of the precise control of the impact energy, the electric screw forging press has no excess energy released on the mold, and the life of the mold is greatly improved. According to statistics, the life of the friction press die is generally below 4,000, while the life of the electric screw press is generally over 15,000 pieces, and some even exceed 50,000 pieces.

- Electric screw forging press can be programmed for forging, can automatically hit multiple times according to the preset multi-step energy.

- When the slider of the electric screw forging press is stationary, the motor does not work and the power consumption is low. More than 20% power saving than friction presses.

- The electric screw forging press has no fixed bottom dead point. It is not necessary to adjust the mold height and it is easy to change the mold. It is easy to adjust the stroke height and the return position is accurate.

- The electric screw forging press has a striking force display to protect the host from overloading.

Automatic Forging Line with Anyang Electric Screw Forging Press in Russia

Electric Forging Screw Press Manufacturers

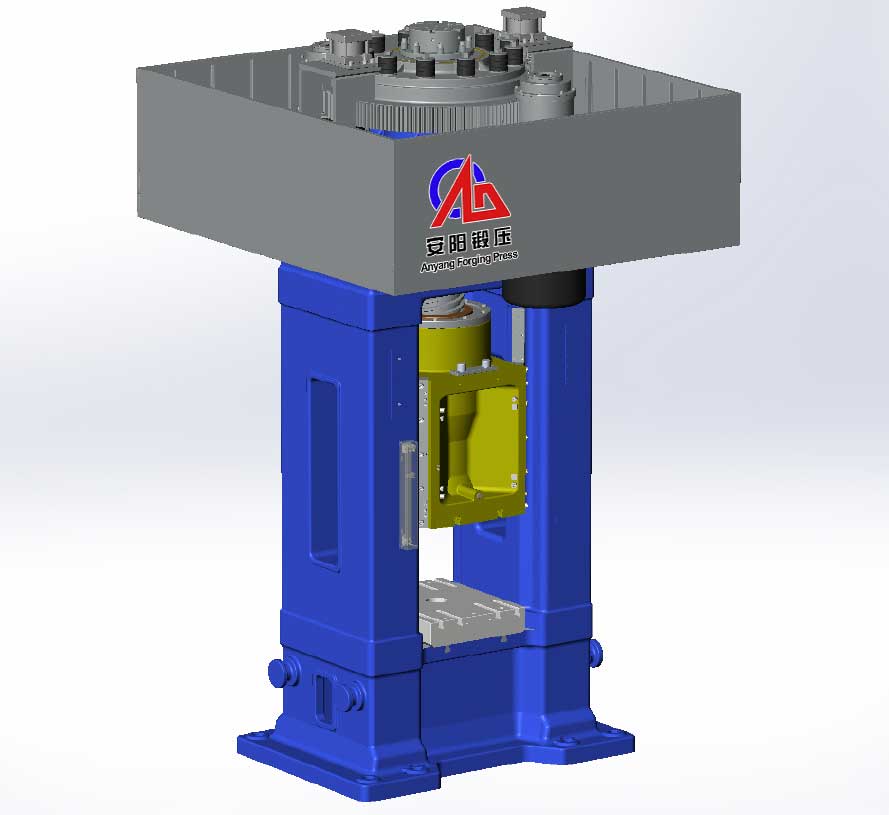

In recent years, with the improvement of the performance and structure of the screw type forging press, its process use has become more extensive. For example, the electric screw forging press produced in Anyang Forging Press has high striking energy, high stroke number, good guiding precision, strong ability to withstand partial load, short mold time after forging and high position of the press at any position of the stroke. The advantages of striking force, etc., provide favorable conditions for multi-turn die forging, precision forging and die forging with large height and large deformation.

Anyang Forging Press can provide the complete turn-key service of electric screw forging press, including design, manufacture, installation, training, maintain, after-sale service, etc. If you are interested in our electric screw forging press, please feel free to contact us.