Working Principle and Application of Rotary Forging Machine

2019-05-18 18:32:07What is Rotary Forging Machine?

The rotary forging machine, also known as orbital forging machine, is a new metal pressure processing technology developed in the 1960s. It is a special forging process in the forging production industry, and can be used for precision production of small and medium forgings.

The Working Principle of Rotary Forging Machine

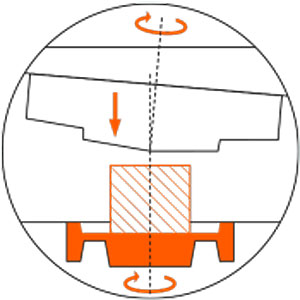

The working principle of rotary forging machine is that, a conical upper die which is rapidly and purely twirled around the center locally presses the end face of the blank, in order to gradually shape the blank. Rotary forging is a continuous local forming method. There is a relatively oblique angle between the center line of the rotary head and the vertical axis of the machine body. The oscillating head of the rotary forging machine is loaded with the metal blank during the oscillating process, and the oscillating head is always subjected to the eccentric load, and the resultant force point continuously orbits around the body axis (ie, rotary forging), that is why the machine is also called orbital forging machine. It is mainly the rolling friction between the oscillating head and the metal blank, the forming pressure of the oscillating weight on the metal blank acts only on a small part of the surface of the workpiece. The forging forming force of a conventional forging press is applied to the entire surface of the end plane of the metal blank.

Rotary Forge Technology

Application of Rotary Forging Machine

- It is especially suitable for semi-axle flanges, pizzas, asymmetric discs, high neck flanges, and special-shaped rods in the automotive, motorcycle, home appliance, equipment manufacturing and forging industries.

- Press forming and blanking of parts with complex shapes, such as automobiles, tractors, battery car rear axles, gears, brake camshafts, and semi-axle bushings.

- Various flanges, cam discs, bowl type pin cutters, gears, disc springs, sprockets, clutch hubs.

- Grid head, cone head.

- Powder metallurgy products, racks, crank connecting rods, tracks for bulldozers, motorcycles with twigs, ratchets, one-way flying blocks, motor claws, car universal joints, ball studs, etc.

Advantages of Rotary Forging Machine

- Compared with the traditional forging machine, rotary forging machine can save about 20%-30% of raw materials. The deformation force of workpiece forming is only 1/5 to 1/20 of that of the conventional forging press method. Thus, it can replace the conventional forging machine whose normal force is 5 to 20 times of the rotary forging machine.

- With a rotary forging machine, the blank can be formed under a hot, warm or cold state. The workpiece blank is evenly deformed, the metal fiber flow direction is reasonable, the dimensional accuracy and surface roughness are high, and the workpiece strength, density, etc. can be improved.

- The die of rotary forging machine has a long service life, low noise and vibration, no environmental pollution, and high production efficiency.

- Easy operation, low investment, simple structure of die. When producing different products, only the insert die need to be replaced.

Choose High Quality Rotary Forging Machine

Anyang Forging Press is the top three forging machine manufacturer in China. With a professional technical team dedicating to the design and manufacturing process of rotary forging machine, we have the ability to provide our customer vertical and horizontal rotary forging machine.

At present, many countries strongly advocate the use of energy-saving, material-saving, and environmentally-friendly equipment, which will put forward higher requirements on the performance, quality and technology of the rotary forging press. Therefore, our company has developed a more specialized, serialized and automated rotary forging press for the market demand, so that the rotary forging process can play a greater role and wider use at home and abroad, providing high-quality equipment guarantee for energy saving and material saving in industries such as automobile, equipment manufacturing and forging and metallurgical powder compaction.

If you are interested in our rotary forging machine, please feel free to contact us, we are confidence to add more power for your forging business!