Improved Claw Pole Forging Process & Automatic Forging Machine Selection

2019-09-07 13:52:31What is Claw Pole?

Claw pole is the core part of the automobile alternator rotor assembly. Its main function is to transform the axial magnetic field generated by the excitation coil in the rotor into the radial magnetic field, so that the three-dimensional distribution of the alternating magnetic field along the space can be obtained when the rotor rotates, the alternating magnetic field generates alternating current relative to the stator motion, so the claw pole of automobile generator is also called the magnetic pole of automobile generator.

At present, the most widely used claw pole forging process at home and abroad is the combination of multi-step hot forging and cold precision finishing. Multi-step hot forging is the core of the process, which mainly includes four steps: upsetting, pre-forging, final forging and trimming. At present, domestic enterprises mainly realize material transfer and automatic graphite spraying between steps by manual. In order to cope with the increasingly fierce market competition and rising labor costs, more and more enterprises are considering the use of automation instead of traditional manual operation-based production lines.

Manual Claw Pole Hot Forging Process

The manual multi-step hot forging process of claw pole is adopted. A hot die forging press is used to arrange four workstations. Two workers are responsible for transferring workpieces and spraying graphite lubricant, and the operation is separated from each other, it can produce 9 to 10 qualified claw poles per minute. At the end of pre-forging, the claw of claw pole pre-forging is vertical upward. In die design, the claw cavity which is difficult to form is designed in the upper die, while the bottom which is simple and easy to form is designed in the lower die. At the end of final forging, the claw of claw pole pre-forging is vertical downward. The step diagram is shown in Figure 1.

Fig. 1 Schematic diagram of manual operation for claw pole hot forging

Advantages of Manual Claw Pole Forging Process

The advantage of this process plan is that the workpiece temperature is high during pre-forging, which ensures that the claw has been basically formed, and the forging scale is easy to fall off from the die cavity, which will not cause the die blockage, and the production process is stable. At the end of forging, the temperature of the workpiece has been reduced and the temperature of the claw is lower than that of the bottom. The forming of local features can be realized by the deformation of the bottom. Moreover, due to the few scales and the complex claw structure, metal flows slowly in the die, it is not easy to produce forging defects such as folding.

Automatic Claw Pole Hot Forging Process

In the forging automation improve plan, automatic forging machine is used to replace manual operation. The steps from pre-forging to final forging and the orientation of work piece placement need to be considered. Manual operation is flexible, and the turnover of work piece does not affect the efficiency and stability of the whole process. The use of automatic forging machine, whether walking beams or robots, will increase the difficulty and cost of automation transformation.

Figure 2 Schematic diagram of automatic claw pole hot forging process

In order to reduce the difficulty of automation transformation, an automation hot forging process scheme based on walking beam is proposed as follows. The step diagram is shown in Fig. 2.

Key Technological Equipment for Automatic Hot Forging Process

In order to realize the above process plan, corresponding process equipment is needed, including feeding device, medium frequency induction heating furnace, blank sorting device, hot die forging press, walking beam mechanism, automatic lubrication device, forming die and so on. The most important for claw pole forging machine is the selection of hot die forging press and the design of walking beam manipulator, lubricating sprinkler and forming die. The rationality of design directly affects the feasibility and stability of claw pole automatic hot forging process.

Automatic Forging Machine of Claw Pole

According to the forming force of each process, the total forming force and the distance between different workstations, the appropriate type of forging equipment is selected. In this process plan, we adopt TMP-2500 hot die forging press imported from Russia with nominal pressure of 2500 tons, as shown in Figure 3.

Figure 3 2500t hot die forging press

Walking Beam for Claw Pole Forging

The walking beam (Fig. 4) is a transmission mechanism for realizing workpiece transfer, the walking beam (Fig. 4) is the transmission mechanism for realizing the transfer of workpiece, five servo motors are used to control the work through the PLC program, it is the core mechanism of forging automation. In this process, the main machine is purchased from Korea, and the manipulator holding the work piece needs to design and optimize the structure according to the actual working conditions, which belongs to the vulnerable parts in the walking beam.

Fig. 4 Walking beam mechanism mounted on die frame

Forming Die for Claw Pole Forging

The forming die consists of three parts: the master die frame, the sub-die frame and the working module. Because the process plan is mainly aimed at claw pole products, the mother die holder is installed in the parts which are not often replaced in the equipment, and is fixed by bolts, there is no need for quick switching. The main position (refers to pre-forging and final forging) sub-die holder adopts hydraulic nut fast tightening method, which can realize fast switching, facilitate the replacement of working modules installed in the sub-die holder, and can significantly improve work efficiency. The sub-die holder is shown in Figure 5.

Fig. 5 Claw pole automatic hot forging die holder

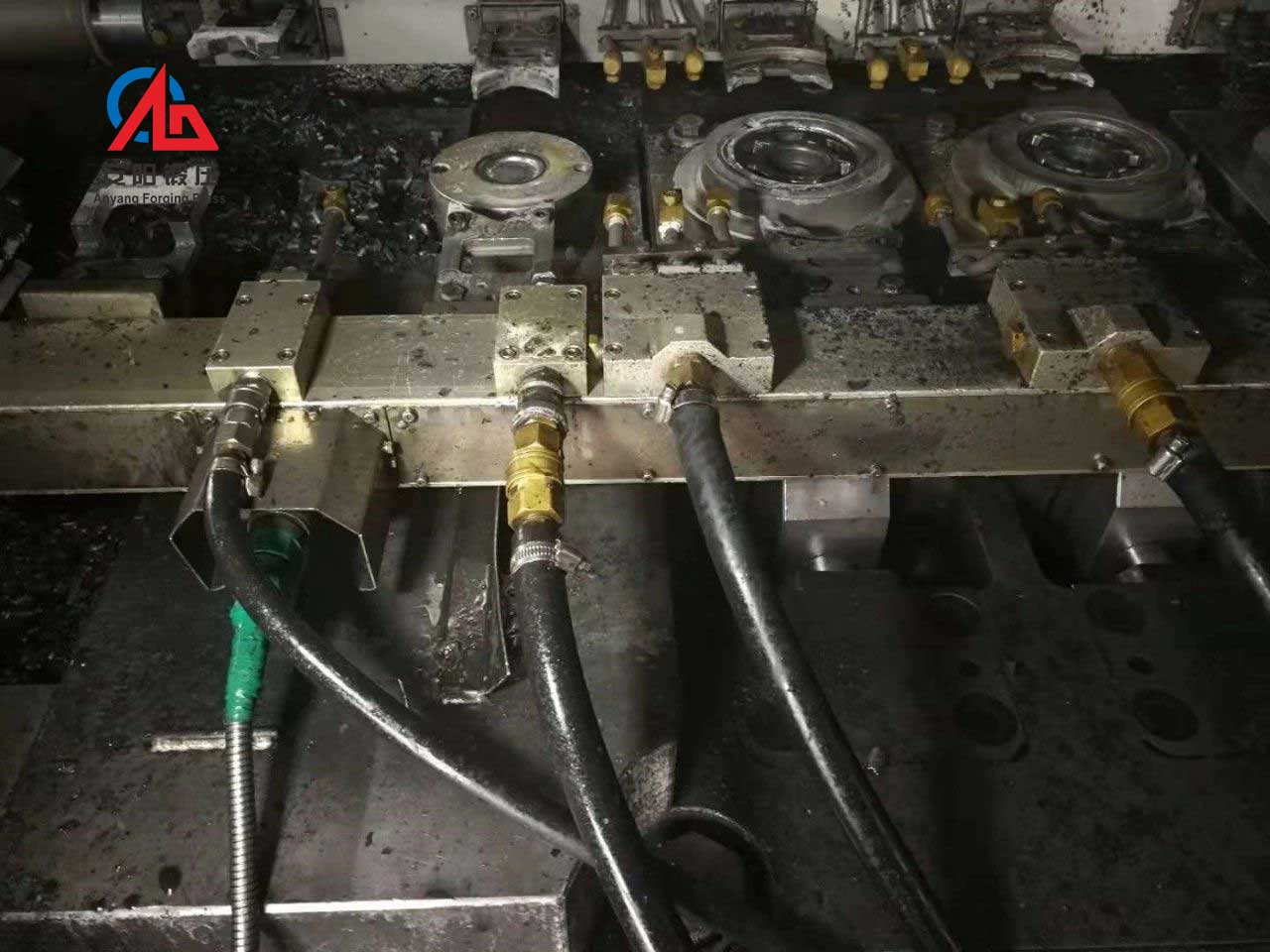

Lubricating Device for Claw Pole Forging

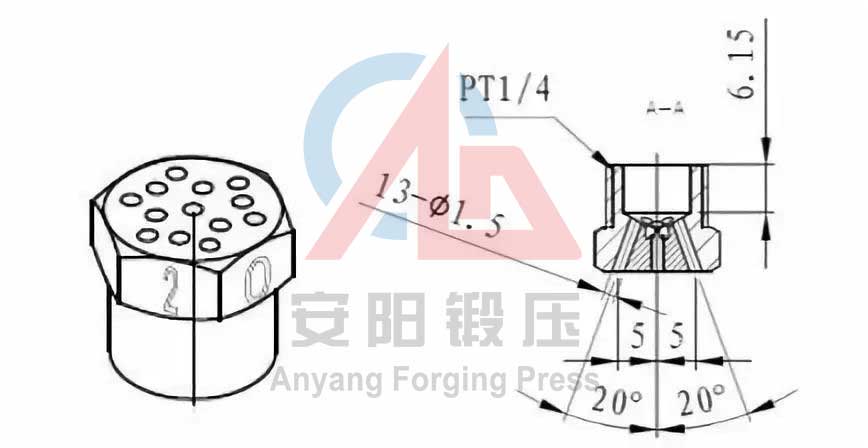

Lubrication device is mainly composed of lubricant mixing box, automatic graphite spraying system and lubricant recovery system. The design of sprinkler in spraying system is very important. The structure shape and aperture size of sprinkler need to be adjusted according to the lubrication part. The geometrical structure of typical spray head is shown in Fig. 6.

Figure 6 Geometric structure diagram of typical sprinkler

Testing Problems of Automatic Claw Pole Forging Process

Because of the difference between the automatic forging process and the existing manual operation process, the die structure and process parameters designed according to the manual operation are not suitable for the claw pole automatic forging. Many problems arise in the early stage of the automatic forging test. It mainly includes the filling dissatisfaction of the claw part, the long air outlet of the claw part and the low service life of the die, which lead to the scrap rate of the product as high as 15%. Several failure modes of the products are shown in Fig. 7.

Failure Cause Analysis of Claw Pole Forging Process

After the analysis and discussion of the test results by engineers and field technicians, the main reasons for the unsatisfactory paw filling and the excessive length of the outlet are summarized as follows:

- Pre-forging die cavity is blocked by oxide scale.

- The lubrication of die cavity is not sufficient and uneven.

- The position of the pier blank in the pre-forging die deviates greatly from the ideal position.

- Distribution of deformation of pre-forging and final forging is unreasonable.

- The main reasons for low die life are as follows:

- The large forming force results in the deformation of the die.

- The long contact time between high temperature billet and die before forming results in the decrease of die hardness.

- Insufficient and uneven lubrication of die cavity leads to worsening of die wear.

Solutions for Automatic Claw Pole Forging Problem

The solutions to these problems are as follows:

- The free pier roughness of the pier step is added to the positioning cavity, i. e. a circular pit is added to the lower die plane of the pier blank. The diameter of the pit is close to that of the model cavity under the pre-forging, which is convenient for the accurate positioning of the pier blank in the pre-forging cavity.

- Optimize the lubricant concentration, spraying pressure and time, the position and size of the outlet hole, and fully and uniformly lubricate the die cavity.

- An air blowing device is added to the walking beam, and the workpiece is cleaned at the same time when the walking beam moves, so as to avoid the residual forging scales in the die cavity.

- Continuously improve the design of die structure, reduce the deviation of die forming force and forming force of different forming steps.

- The working parameters of walking beam are adjusted to reduce the contact time between high temperature billet and die cavity.

Improved Claw Pole Forging

By improving the structure of die flash, adjusting the way of air outlet and lubrication, the quality problems such as insufficient forming of claw tip and the length of air outlet were solved, and stable production began. The improved physical photos are shown in Figure 8.

Figure 8 Improved Claw Pole Forging

Advantages of Claw Pole Forging Automation

Forging automation is the inevitable trend of future forging industry development, after more than one year's exploration and improvement, we have realized the automatic hot forging of claw pole products. The production rhythm can reach 14-15 pieces per minute at the fastest, the average output of the shift is 4800 pieces, and the average life of the die is close to the manual forging level. In the later stage, we plan to increase the production rhythm to 16-17 pieces per minute through continuous improvement.

Best Claw Pole Forging Machine Manufacturer from China

Anyang Forging Press is the biggest forging machine manufacturer in China, we have exported forging machine to more than 74 countries and regions since 1956. For claw pole forging, we have forging hammer and hydraulic forging press for you to choose.

With more than 60 years in forging machine manufacturing, we have ability to provide the complete forging line machine solution from design, manufacture, installation, training, after-sale service. The complete automatic claw pole forging line machine include induction heating machine, pre-forging machine, robot, automatic forging hammer, forging press, automatic graphite spraying machine, transforming device, heat treatment machine, etc. All of these machine have been test by our customers, and are highly praised because of the high quality.

If you are also looking for claw pole forging machine, please feel free to contact us. Anyang Forging Press will not let you down!