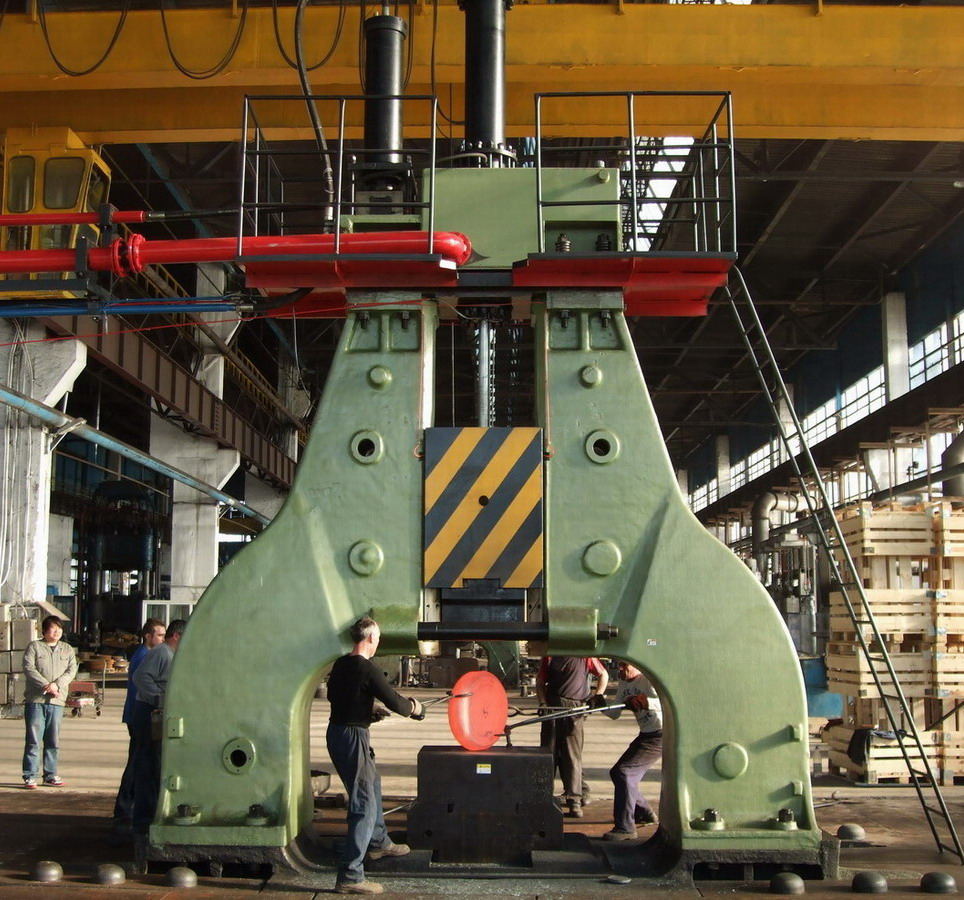

electric hydraulic open die and close die forging hammer

2017-12-22 09:26:49

electric hydraulic open die and close die forging hammer

electric hydraulic forging hammer, electric hydraulic head by An yang Forging Machinery Industry Co., Ltd. successfully developed hydraulic gas hammer,hydraulic gas head replacement products, our company has its own patented technology. Its main advantages are energy saving and environmental protection, high efficiency, low failure rate, improving the working environment of workers and reducing the labor intensity of the hammer.

The primary energy utilization rate of the steam forging hammer is less than 2%, and some even as low as 0.2%. However, the primary energy utilization of the full hydraulic electro-hydraulic power head can reach 20%. Through the full hydraulic power head reconstruction, the energy-less air is eliminated Power system to restore the operation of equipment accuracy, so the energy-saving rate of up to 90%, improve the forging capacity of the equipment, greatly reducing energy consumption and reduce production costs.

The principle of full hydraulic drive electric-hydraulic hammer determines its energy enough , fast frequency, no stew mode, low failure rate .

electric-hydraulic hammer advantage

1, put an end to the hammer rod piston oil and gas cross-string and leakage problems, eliminate the bottom of the cylinder liner oil channel cross-channeling and leakage problems;

2, there is no back pressure on the piston cavity on the return trip, the return speed is increased, the attack frequency is accelerated, so the productivity is significantly increased;

3, Remove the master cylinder gas system and vice gas tank, so that the structure is simplified;

4, due to the improvement of the working environment of the hammer piston seal, at the same time due to the reduction of the seal requirements of the hammer piston, so that the life of the seal greatly improved, the number of changes significantly reduced;

5, because the piston is usually high pressure under the cavity, it hit the hammer after the return journey is not delayed, stew mode time is short, mold (anvil) life expectancy, and facilitate workers to flip the work piece;

6, the impact of system pressure less factors, so easy to achieve precise control of the blow energy

Electric hydraulic die and open die forging hammer application

Electric hydraulic closed die forging hammer both are mainly applied in batches production of all kinds of die forgings,such as automobile forgings,tractor forgings,agricultural equipment forgings, oil and gas industry die forgings, electrical power station die forgings and industrial forgings.

Electric hydraulic open die forging hammer both are widely accepted in modern open die forging plants, suitable for producing various open die forgings, such as shaft forgings, ring forgings, gear blanks, flanges etc.

Electric hydraulic forging hammer parameter

Electric hydraulic close die forging hammer

|

|

单位

|

C86Y-25

|

C86Y-50

|

C86Y-75

|

C86Y-125

|

C86Y-200

|

C86Y-250

|

C86Y-400

|

C86Y-550

|

|

Hit energy

|

kJ

|

25

|

50

|

75

|

125

|

200

|

250

|

400

|

450

|

|

Hammer weight

|

kg

|

1000

|

2000

|

3000

|

5000

|

8000

|

10000

|

16000

|

18000

|

|

Max stroke

|

mm

|

1000

|

1200

|

1250

|

1300

|

1350

|

1400

|

1500

|

1500

|

|

Hit frequency

|

Min-1

|

55-70

|

55-70

|

55-70

|

55-65

|

50-60

|

50-60

|

50-55

|

45-55

|

|

Motor power

|

kW

|

1*75

|

2*75

|

3*75

|

4*75

|

5*75

|

6*75

|

8*75

|

10*75

|

Electric open die hydraulic forging hammer (double arm )

|

|

单位

|

C66Y-35

|

C66Y-70

|

C66Y-120

|

C66Y-140

|

C66Y-175

|

C66Y-210

|

C66Y-245

|

C66Y-350

|

|

Hit energy

|

kJ

|

35

|

70

|

120

|

140

|

175

|

210

|

245

|

350

|

|

Rated weight of

falling parts |

kg

|

1350

|

2600

|

3750

|

4400

|

5700

|

6600

|

7500

|

10000

|

|

Max stroke

|

mm

|

1000

|

1260

|

1450

|

1450

|

1730

|

1800

|

1850

|

1950

|

|

Hit frequency

|

Min-1

|

80-160

|

75-120

|

65-100

|

60-95

|

50-95

|

45-90

|

45-85

|

40-75

|

|

Motor power

|

kW

|

55*2

|

55*3

|

55*4

|

55*5

|

55*6

|

55*7

|

55*8

|

55*10

|

Electric open die hydraulic forging hammer (single arm )

|

|

单位

|

C61Y-30

|

C61Y-70

|

C61Y-105

|

C61Y-140

|

C61Y-175

|

C61Y-210

|

C61Y-245

|

C61Y-280

|

|

Hit energy

|

kJ

|

30

|

70

|

105

|

140

|

175

|

210

|

245

|

280

|

|

Rated weight of

falling parts |

kg

|

1350

|

2600

|

3750

|

4400

|

5700

|

6600

|

7500

|

8000

|

|

Max stroke

|

mm

|

1000

|

1260

|

1450

|

1450

|

1730

|

1800

|

1850

|

1900

|

|

Hit frequency

|

Min-1

|

80-160

|

75-120

|

65-100

|

60-95

|

50-95

|

45-90

|

45-85

|

40-75

|

|

Motor power

|

kW

|

55*2

|

55*3

|

55*4

|

55*5

|

55*6

|

55*7

|

55*8

|

55*9

|

If you are interested in electric hydraulic forging hammer , we can sent technical parameters and quote for you .

Sophia Zhou (Ms)

please contact 0086-372-3389658

whatsapp : +8618317777443

wechat: +8618317777443

Skype : +8618317777443

email : sophia@anyanghammer.com

website : www.chinesehammers

Facebook :https://www.facebook.com/anyany.mali